AS/NZS 2161 is the standard that covers occupational protective gloves in Australia and New Zealand. This series of standards ensures the correct gloves are chosen and maintained to provide users with effective protection.

Do Elliotts’ gloves meet the requirements of Australian Standards for gloves?

Elliotts places a great amount of focus on quality and standards, promoting the need for gloves to be certified to AS/NZS 2161 standards. Where possible our gloves are certified by BSI to AS/NZS 2161 standards. If the gloves are not certified, they are manufactured to meet the requirements of the standards.

What are the most common glove standards?

- AS/NZS 2161.3:2020 (EN388) Protection against mechanical risks

- AS/NZS 2161.4:1999 (EN407) Protection against thermal risks (heat and fire)

- AS/NZS 2161.5:1998 (EN511) Protection against cold

- AS/NZS 2161.10.3:2005 (EN 374) Determination of resistance to permeation by chemicals

AS/NZS 2161.2:2020 (ISO 21420) General Requirements

This standard defines the general requirements and relevant test procedures for all protective gloves and is concerned with the following areas:

- Glove design and construction

- Resistance of glove materials to water penetration

- Innocuousness

- Comfort and efficiency

- Marking and information supplied by the manufacturer

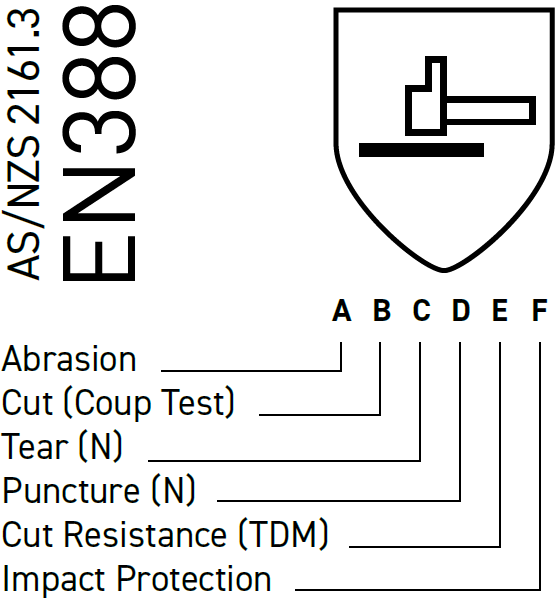

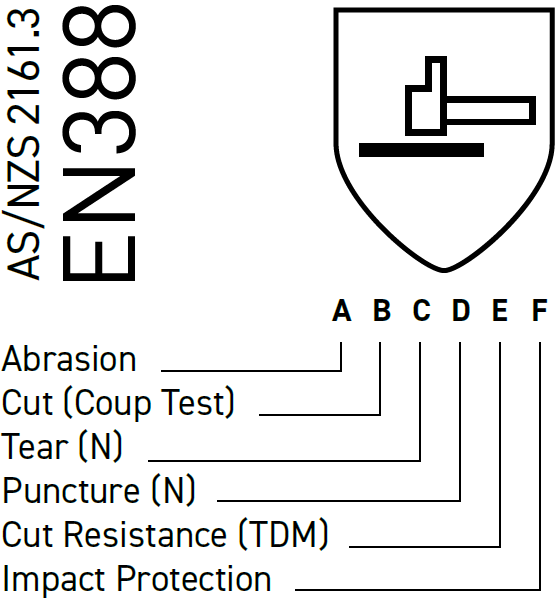

AS/NZS 2161.3:2020 - Protection Against Mechanical Risks (EN388)

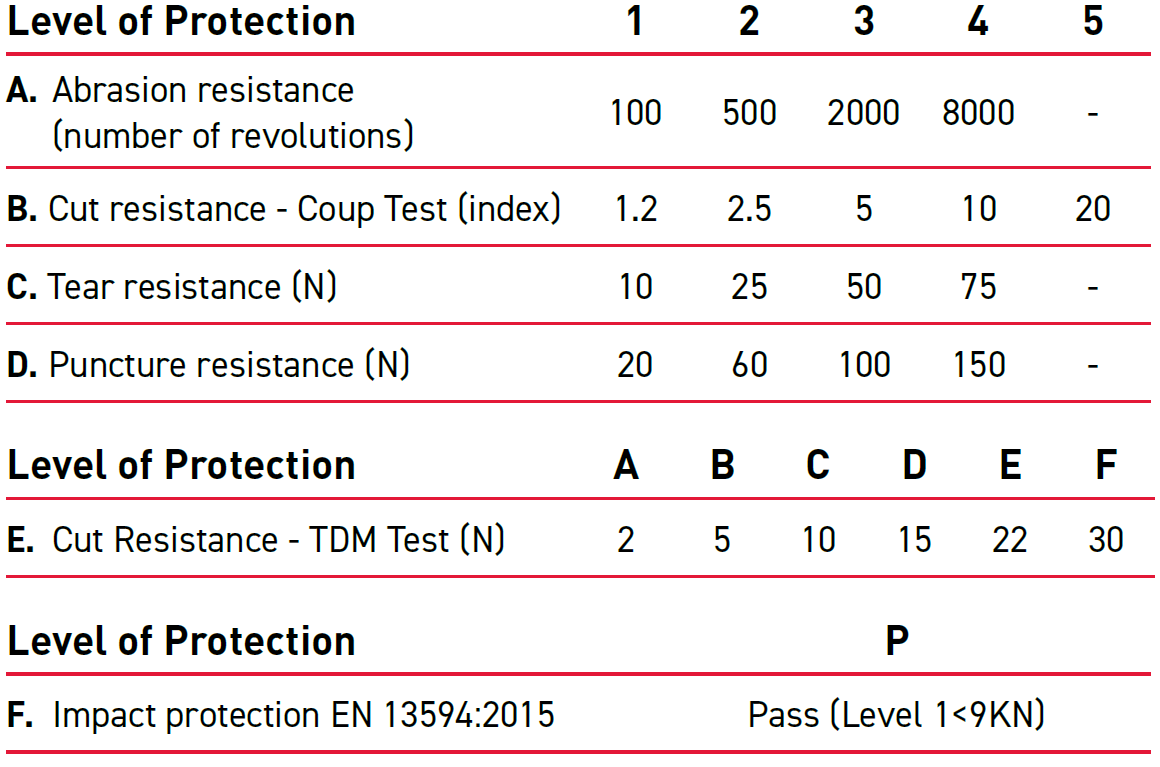

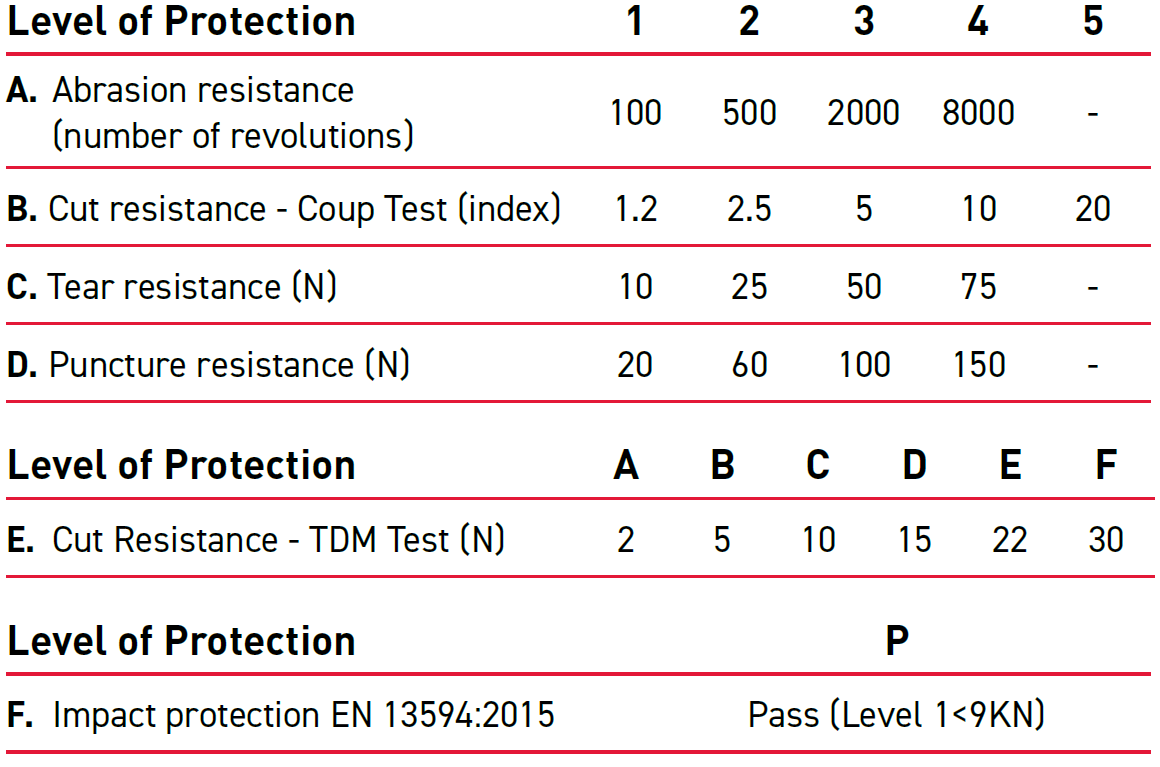

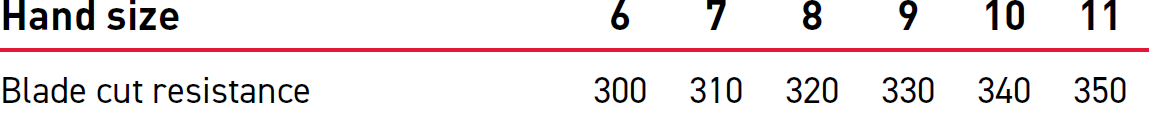

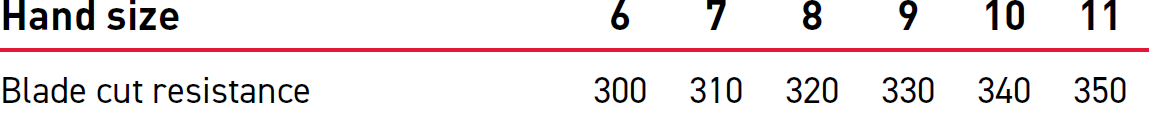

Mechanical risk is the risk caused by abrasion, blade cut, tear and puncture to the wearer of the glove. A tested item is given a performance rating of 1 to 4 (lowest to highest) on some or all of the listed categories. The ‘blade cut resistance’ test is an exception as it measures from 1 to 5. Frequently an ‘x’ will replace one or more of the numbers, this means that the corresponding test was not performed.

In the latest update to the standard, two further tests were introduced. The first of which negates the need for the ‘blade cut resistance’ test and instead uses the TDM method, which produces a score of A-F and an Impact Protection test with produces a Pass or Fail.

The performance values assigned against each test factor correspond approximately to the following values:

- Abrasion Resistance - How well can the material of the glove resist exposure to repeated abrasion?

- Cut Resistance (Coup Test) - How well can the material of the glove resist cutting objects?

- Tear Resistance - What force is needed to enlarge, by tearing a precut hole in the material of the glove?

- Puncture Resistance - What force is needed to puncture the palm of the glove with a calibrated spike?

- Cut Resistance (TDM Test) - How well can the material of the glove resist cutting objects using the new TDM test?

- Impact Resistance - How impact-resistant is the glove? With an impact energy of 5 joules, the transmitted force should be equal to or less than 9kN for a single hit and the average should be equal to or less than 7kN. If the requirements are fulfilled, the glove will be marked with a P (Pass). If a fail, there will be no marking.

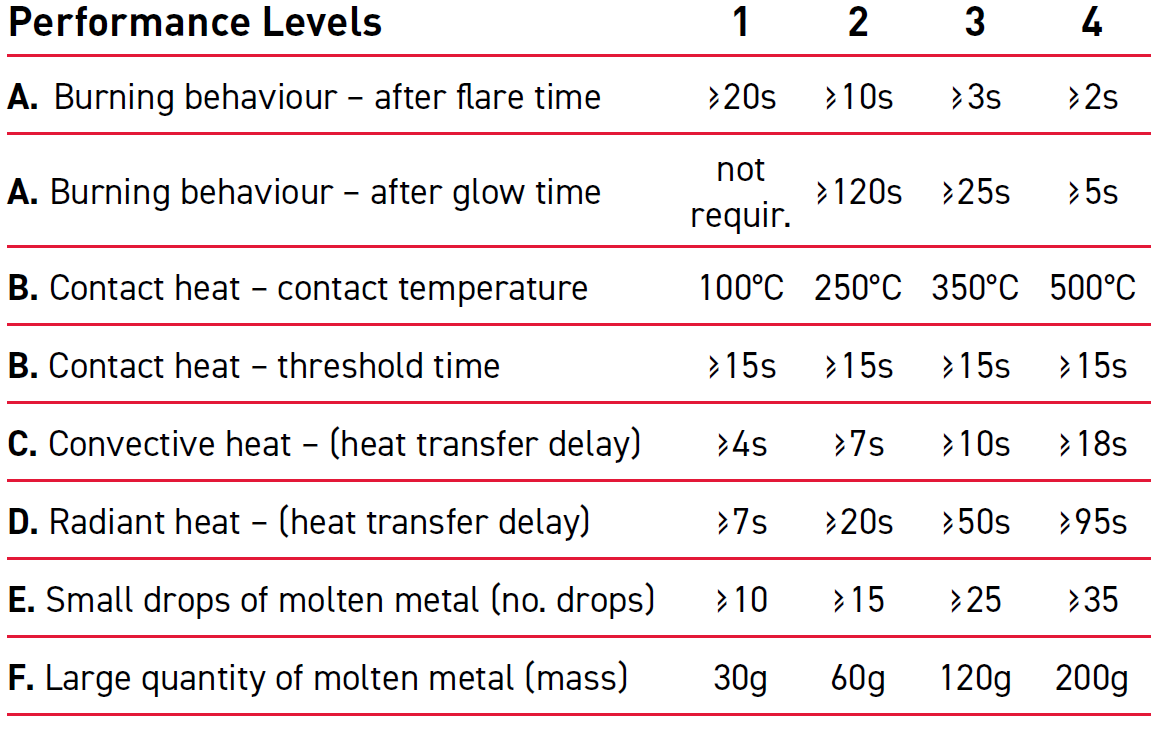

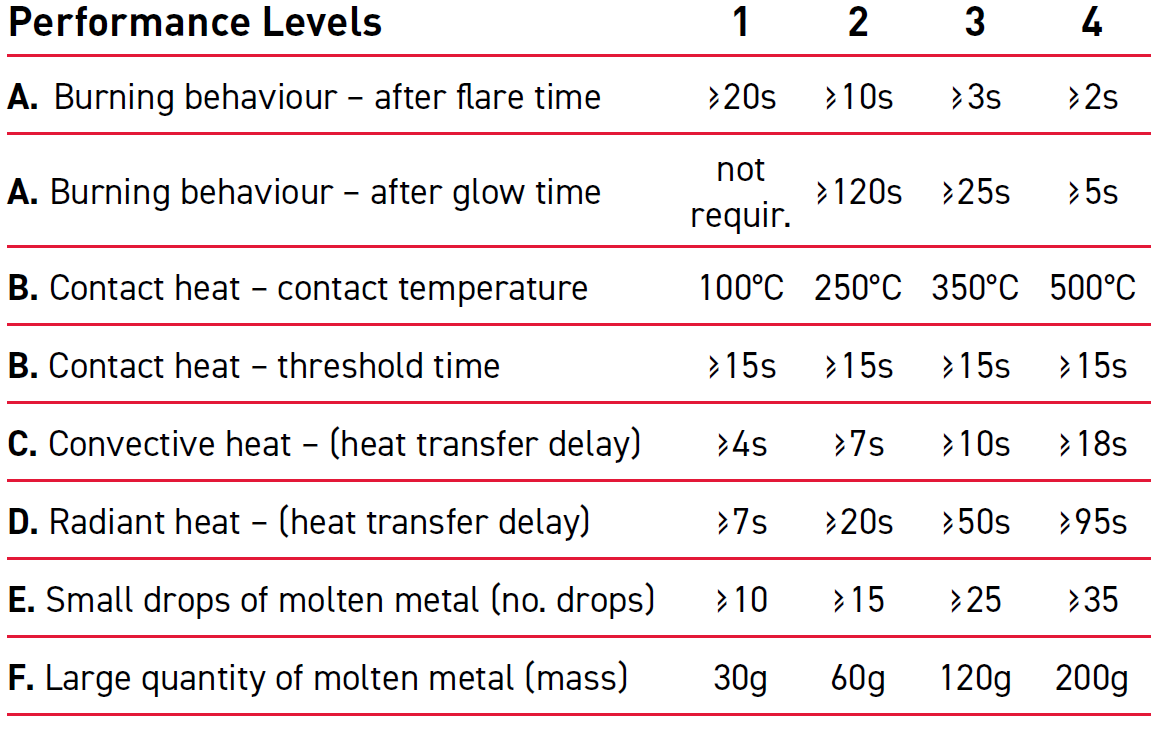

AS/NZS 2161.4:1999 - Protection Against Thermal Risks (Heat and Fire) EN407

A tested item is given a performance rating of 1 to 4 (lowest to highest) on some or all of the listed categories. Frequently an ‘x’ will replace one or more of the numbers, this means that the corresponding test was not performed.

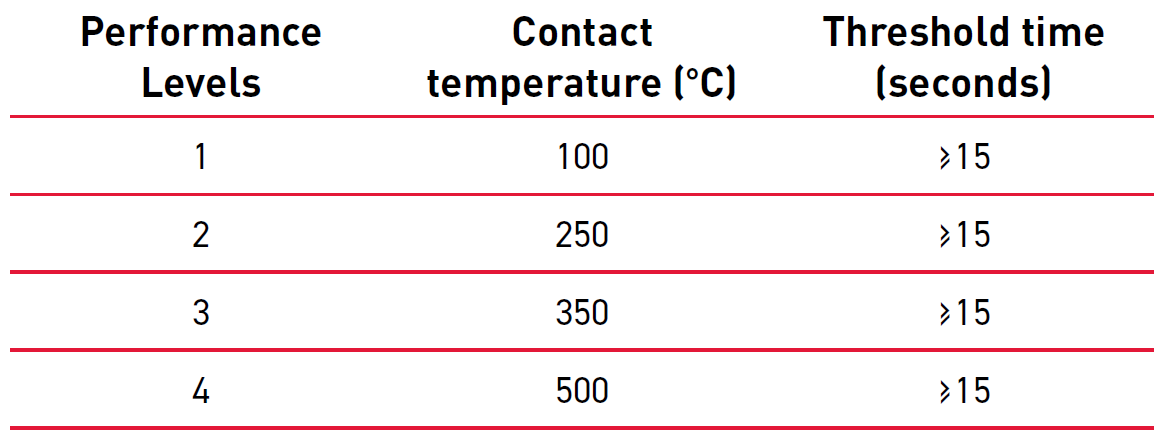

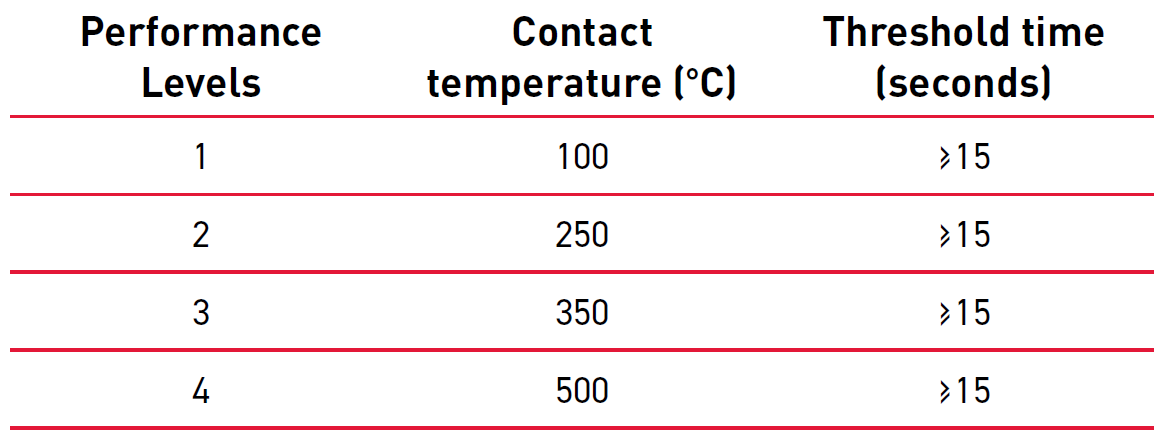

The following table details the performance levels for the ‘contact heat’ category:

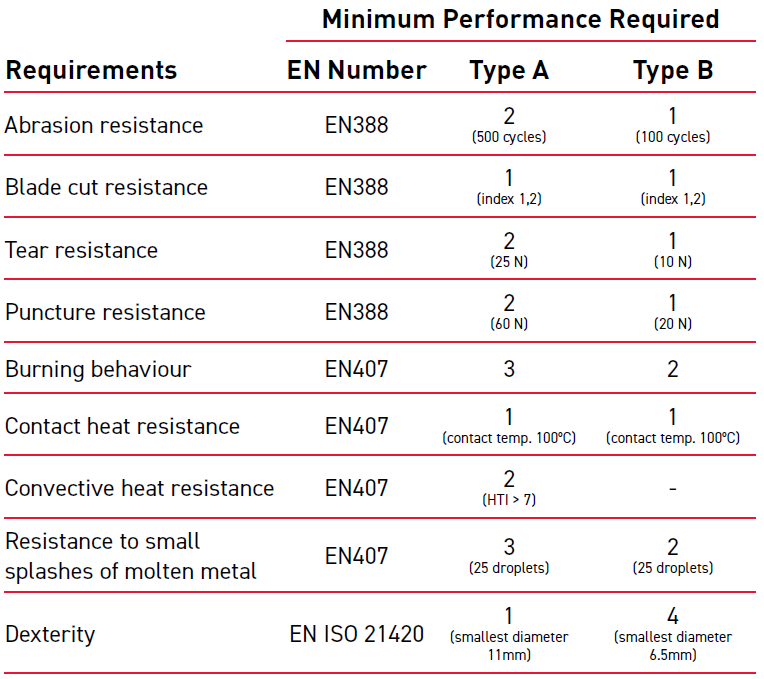

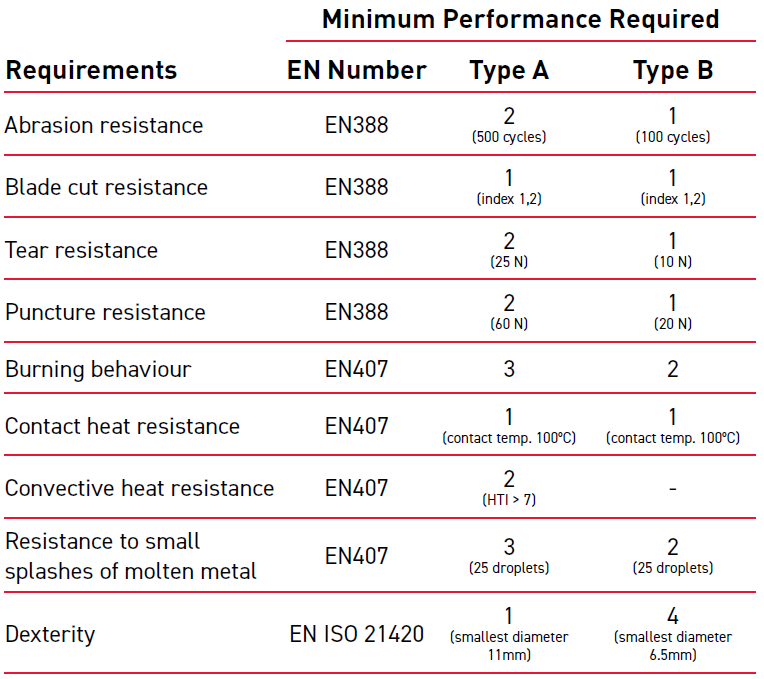

EN12477 Protective Gloves for Welders

The standard specifies the requirements and test methods for the gloves used for manual welding of metals, cutting and related techniques. The welder’s gloves are classified into two categories. B when dexterity is required and A for other welding processes.

Protective gloves for welders protect the hands and the wrists during the process of welding and related tasks.

In addition to mechanical hazards, protective gloves for welders protect against small splashes of molten metal, short contact exposure to limited flame, convective heat and contact heat and UV radiation from the arc. The glove’s material provides minimum electrical resistance up to 100 V (DC) for arc welding. Protective gloves shall comply with the requirements of EN ISO 21420:2020 except for the lengths. The minimum lengths are defined in the table below.

Gloves will be tested and according to the test results be classified as either:

- Type A: lower dexterity (with higher performance for physical characteristics such as abrasion, tear, puncture and convective heat resistance) recommended for all welding processes.

- Type B: higher dexterity (with lower physical performance) is recommended for TIG welding.

The two types of gloves are subject to different minimum performance requirements under EN 388:2020, EN407:2004 and EN ISO 21420:2020.

In addition to the mandatory tests listed above, the standard now details an optional test intended for arc welding applications. Using EN 1149-2, electrical resistance is measured by attaching electrodes to either side of the material and applying a DC voltage between them. The resulting electrical resistance is then measured.

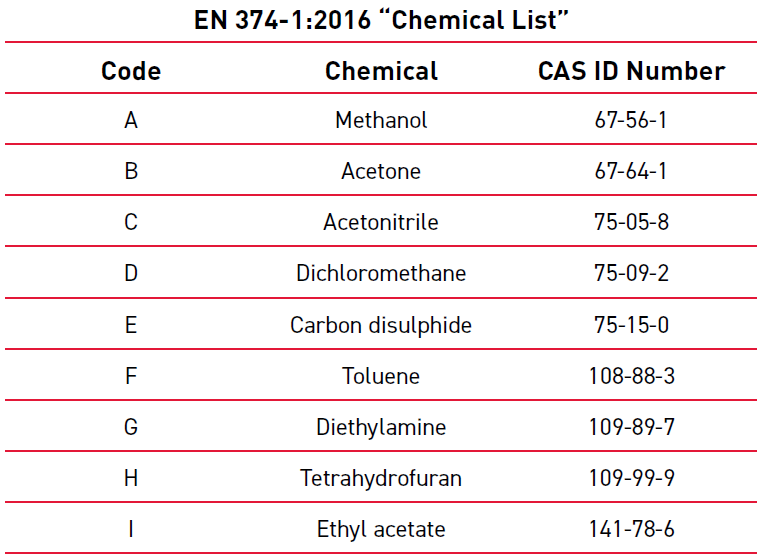

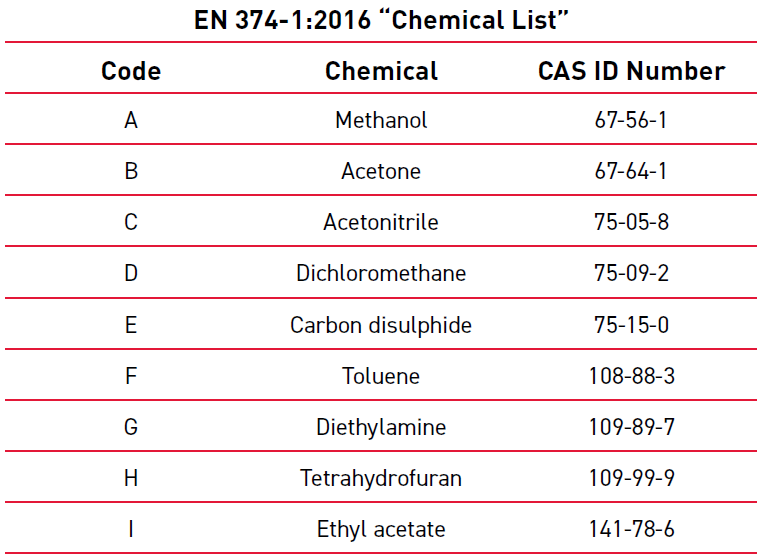

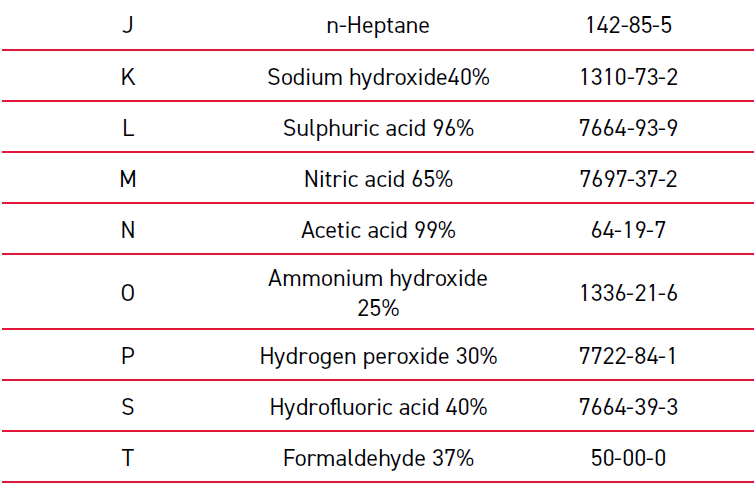

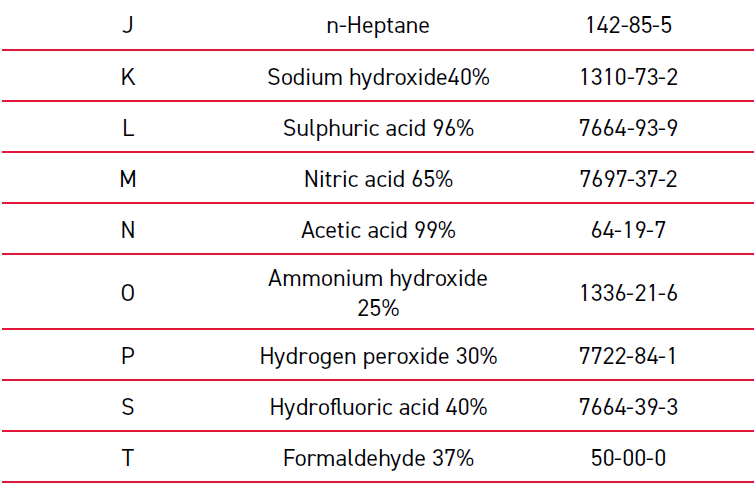

AS/NZS 2161.10:2005 (EN374) - Determination of Resistance to Permeation by Chemicals.

The latest changes to the EN 374 certification brought with it a number of new tests to ensure better consistency between test results and a better breadth of chemicals tested.

Part 1: EN ISO 374-1:2016 – Terminology and performance requirements for chemical risks'

When a glove is tested, 3 samples are taken from the palm, and for gloves longer than 400mm, 3 additional samples are taken from the cuff to be tested for permeation and degradation.

Permeation testing – how rapidly does the chemical penetrate?

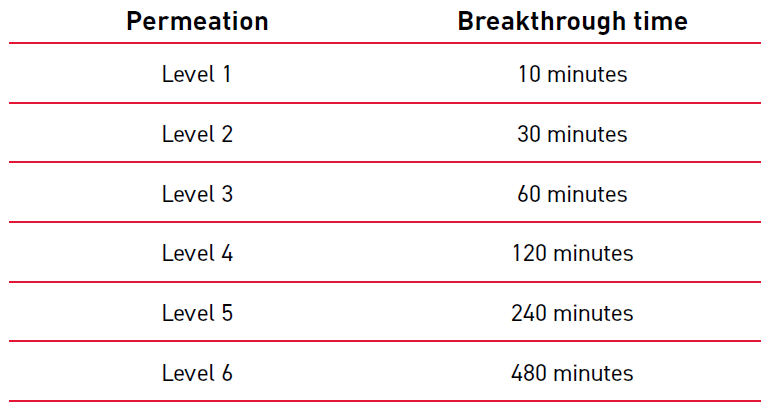

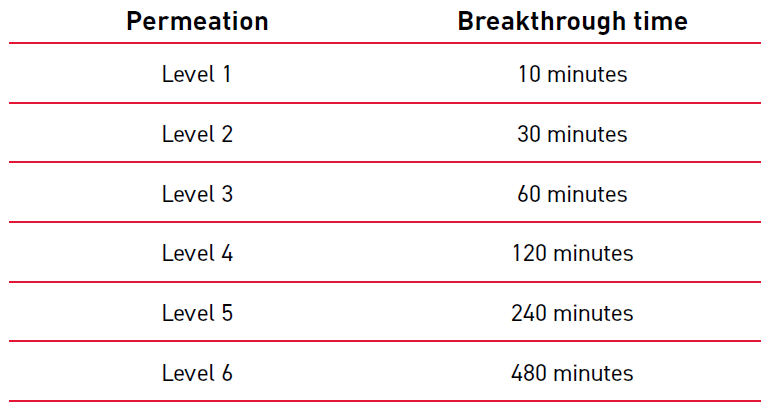

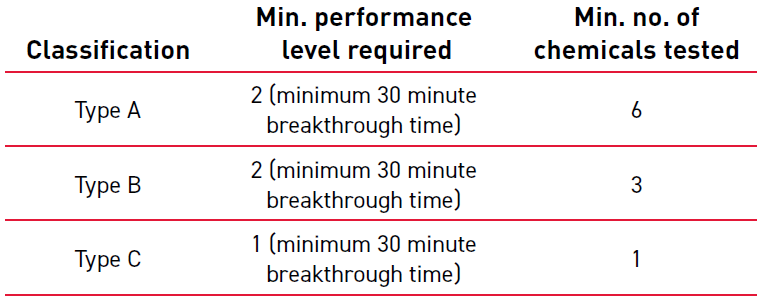

Permeation is measured in terms of breakthrough time, which is the time it takes for a chemical to penetrate the glove material. For the lowest level, Level 1, the time is at least 10 minutes. The highest level is Level 6, for which the breakthrough time is at least eight hours.

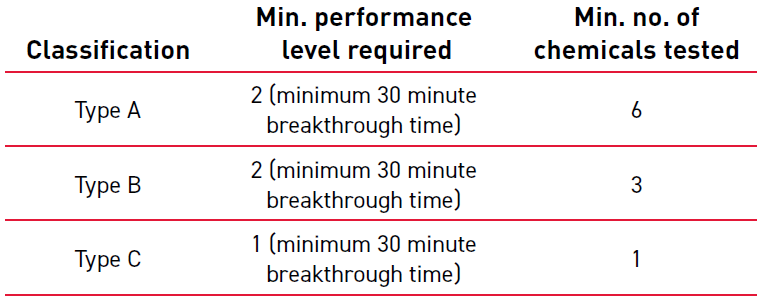

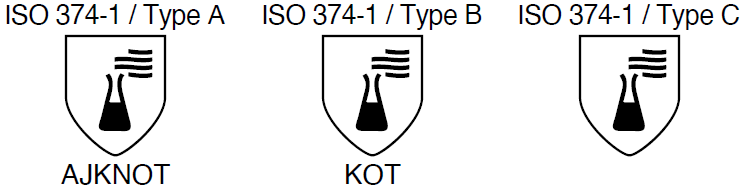

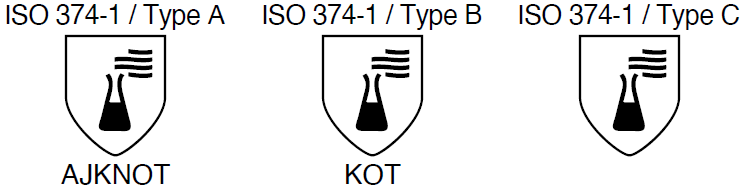

Gloves are then separated into three classification types

based on the above permeation performance. Type A,

Type B, and Type C.

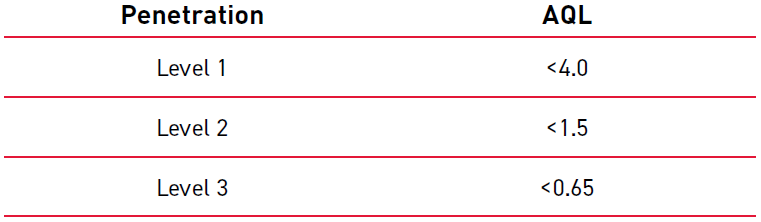

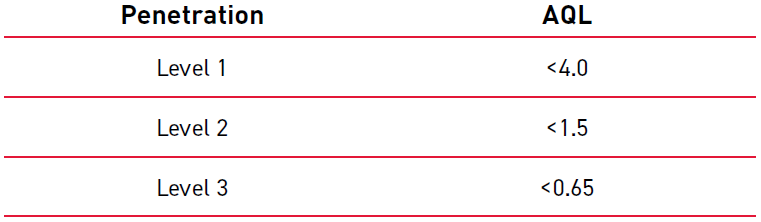

Part 2: EN ISO 374-2:2014 – Determination of resistance to penetration Penetration testing – is the glove leakproof?

Gloves that are to give protection against micro-organisms and chemicals must be impenetrable (without holes). In the case of thin, disposable gloves, penetrability is tested by filling the glove with water or air.

If the water or air leaks out, the glove is deficient. The results are expressed in terms of the highest number of deficient gloves per hundred, described as the acceptable quality level (AQL).

Part 4 – EN 374-4:2013 – Determination of resistance to degradation by chemicals

This is a mandatory test for all chemical gloves. The puncture resistance of the glove material is measured after continuous contact with its external surface with a challenging chemical. The test is carried out using the following method.

- 6 sections are cut from each of the 3 gloves.

- For each glove, 3 sections are exposed to test chemicals for 60 minutes and 3 are left untouched.

- Degradation is calculated on the average change in force required to puncture the section from unexposed to exposed as a percentage.

Part 5 – EN 374-5:2016 – Terminology and performance requirements for micro-organisms risks

This section is split into two ISO 374-5:2016 classifications.

- Protection against bacteria and fungi

- Protection against viruses, bacteria, and fungi.

Elliotts’ Chemical gloves are only tested to classification one.

WARNING Heat and wear affect the glove’s resistance to chemicals. A glove that gives protection against one chemical may perform poorly in relation to another.

IMPORTANT All gloves must be thrown away (in the hazardous waste bin if required) no more than 8 hours after initial contact with the chemical.

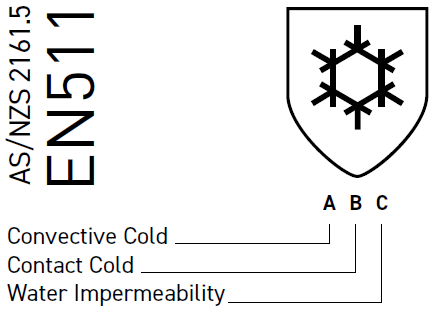

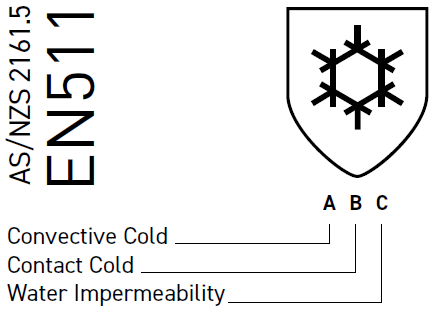

AS/NZS 2161.5:1998 Protection Against Cold (EN511)

The standard applies to any gloves to protect against convective and contact cold down to -50°C. Protection against cold is expressed by a pictogram followed by a series of 3 performance levels relating to specific protective qualities. The “cold hazard” pictogram is accompanied by a 3-digit number.

A = Resistance to convective cold (Levels 1-4)

This is measured based on the transfer of cold through the glove via convection. A model hand heated to body temperature is subjected to a cold room; the resistance to the room’s climatic temperature and also the energy required by the hand to maintain a constant temperature are both measured to arrive at a final score.

B = Resistance to contact cold (Levels 1–4)

This measures how protective the garment is when put into direct contact with a cold object or source. The ample is placed between a warm plate and a cold plate before an extractor fan is used to cool both plates further, the results are then compared to a reference standard, and a final level is decided.

C = Water Proof/ Permeability by water (Levels 0-1)

These tests ensure that your hands will be completely safe from water seeping in and are simply a pass or fail - if the glove cannot withstand water permeating its fabric after 30 minutes of exposure it will fail. Receiving a Level 0 on this test does not necessarily mean these gloves do not perform highly in the other two areas and can still earn them accreditation.

All gloves that achieve this standard must also pass at least level 1 of the EN 388 abrasion tests.

REFERENCE PAGES:

Glove & Hand Protection Introduction | Glove & Hand Protection Range | Glove & Hand Protection Materials | Glove & Hand Protection Glossary | Glove & Hand Protection FAQs