Meet the new Australian Standard in Glove Safety

The Latest Australian Standard in Glove Safety

When it comes to lifting the standard of hand protection, Elliotts don’t just talk about it, we lead by example. Elliotts were the first to have our gloves certified to Australian Standards back in 2011 and we will now be certifying our gloves to the new glove standard AS/NZS 2161.3:2020 Occupational protective gloves Protection against mechanical risks.

We have been testing many of our safety gloves to the new version and now that the standard is published you will notice our labelling and packaging start to change to include the new AS/NZS 2161.3:2020 version.

What’s changing in the new standard AS/NZS 2161.3:2020?

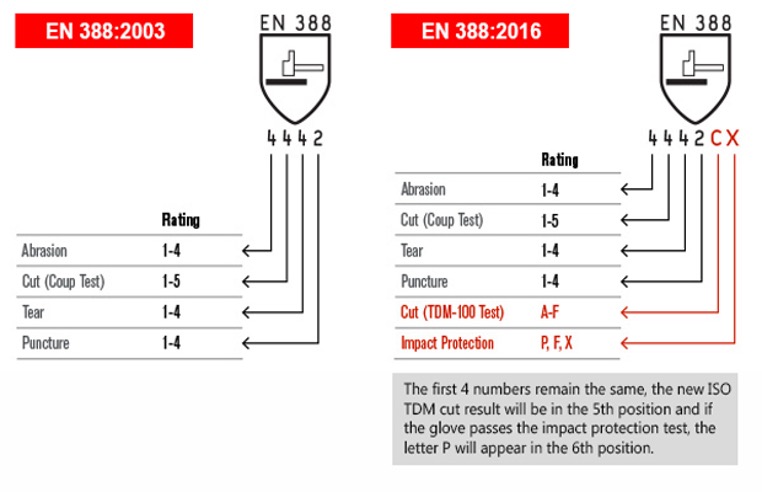

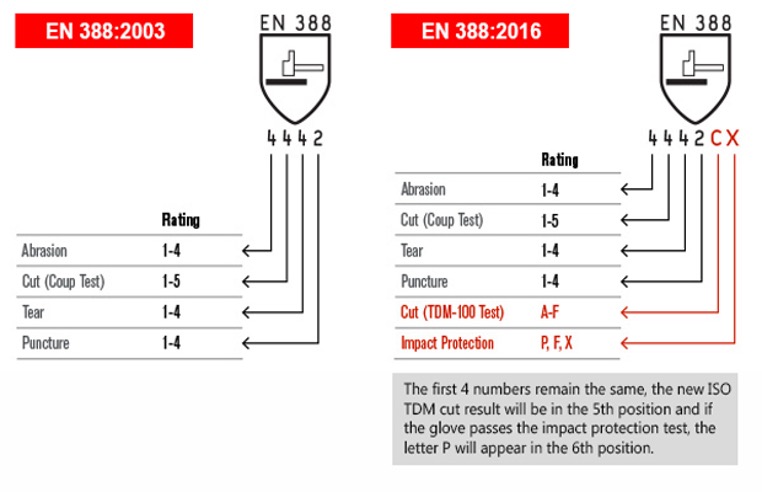

AS/NZS 2161.3:2020 now mirrors the European standard EN 388:2016 Protective gloves against mechanical risk. So what has changed, what’s new, and what stays the same?

Testings on resistance to abrasion, tear and puncture are carried out as they were before with minor clarifications to testing procedures and materials. The test results correspond the same way they did in the 2003 version with ratings of 0-4, with 4 being the highest performance level.

The main difference in the 2016 edition is in relation to cut resistance and impact protection. The new version now has two cut resistant methods:

Cut Resistance Testing

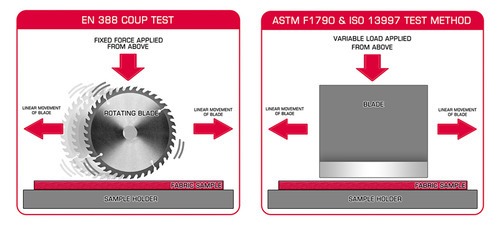

1. Existing Method - (Coup method)

Under the EN 388 glove standard, introduced in 2003, cut resistance is measured with a Coup test machine. A section of fabric is placed in a holder and a rotating circular blade is moved back and forth at a constant speed, pressing down with a force of 5 Newtons. When the blade cuts through, a performance rating from 1 to 5 is calculated from the total distance of travel. The blade gradually loses sharpness, so at the start and finish it is calibrated using cotton fabric. Therefore, the result can be less accurate for gloves with a higher cut-resistance. This test method remains in the 2016 version but is only to be used for materials that do not affect the sharpness of the blade.

2. New Method - EN ISO 13997 (TDM method)

TDM is an abbreviation for the equipment used to conduct this test, a tomodynamometer. This test involves a straight blade being drawn across the sample in one movement, with a new blade every time. The 'stroke length' before cut-through is recorded for a range of forces and graphs plotted to predict the force required to cut through the glove in 20mm of travel. This force is used to calculate a score from A to F, with F being the highest rating.

Impact Protection

Impact verification has been added to EN 388: 2016. The test method is taken from the motor cycle standard EN 13594:2015. The area where the impact protection is claimed to be tested, but due to technical reasons, the area around the fingers cannot be tested.

With impact energy of 5 joules, the transmitted force should be equal to or less than 9kN for a single hit and average should be equal or less than 7kN. If the requirements are fulfilled, the glove will be marked with a P (Pass). If a fail, there will be no marking.

Glove Markings and Levels of Performance

CONTACT US

Elliotts will begin rolling out this new certification as new shipments of gloves arrive. If you want to know more, speak with your Regional Sales Manager or contact the Elliotts customer services team on 07 3265 2944 or send us a message.