Elliotts Welding Screens and Frames

Elliotts range of welding screens has been specifically engineered to:

1. eliminate dangerous Ultra Violet Radiation

2. minimise the glare of high-amperage welding arcs

3. increase welding booth illumination without significantly reducing visibility through the screen

Welding Screens - How Do They Work?

The ArcSafe welding screen is manufactured from vinyl film, processed with a colour dye, a flame retardant and an ultraviolet absorber. The dye consumes and filters the blue light brightness associated with the electric arc welding process. The material surface acts as a reflector, causing the arc to appear larger and less bright, thus reducing glare to the eyes. The light is also scattered in different directions, creating a fluorescent light. This causes the pupil to constrict and shut out excess glare, thus reducing light to the retina.

Colours and Luminance

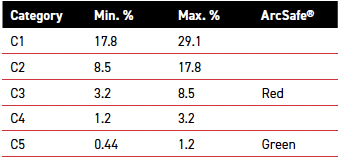

ArcSafe welding screens are available in two colours: Red and Green. The luminance Transmittance is the ratio of the luminance of a source of light when viewed through a curtain or screen, to the luminance of that source when viewed directly.

Benefits of ArcSafe

ArcSafe welding screens absorb the dangerous ultraviolet light that is emitted from the arc welding process and also offer these additional benefits:

- Surrounding your welding situations with safety

- Protecting your co-workers and other people from the painful effects of accidental welding flash

- Safely and quickly defining hazardous welding areas

- Allowing safe observation for a safety check of welding operations

- All seams are welded, not sewn, for extra durability and strength

See our range of Welding Screens & Frames.

REFERENCE PAGES:

Welding Gear Introduction | Welding Gear Blankets & Drapes | Welding Gear Materials | Welding Gear FAQs